Facilities & Capabilities

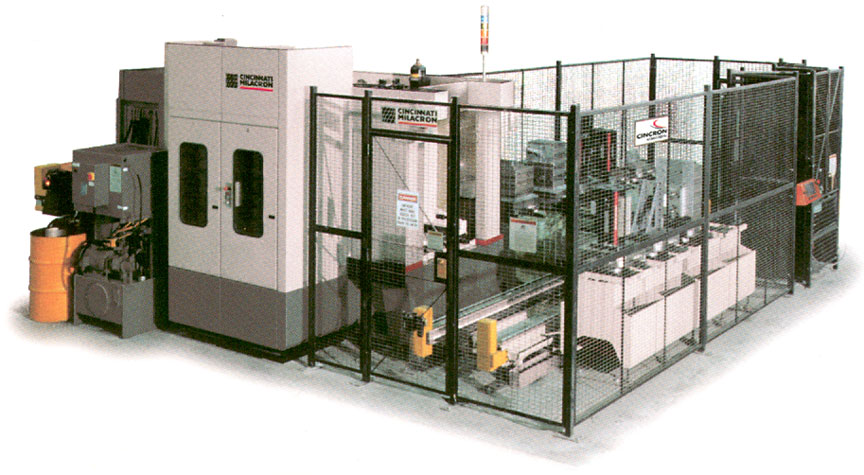

State-of-the-art horizontal Machine Center with automatic pallet changing is just one example of BOBALEE's commitment to continuous process improvement.

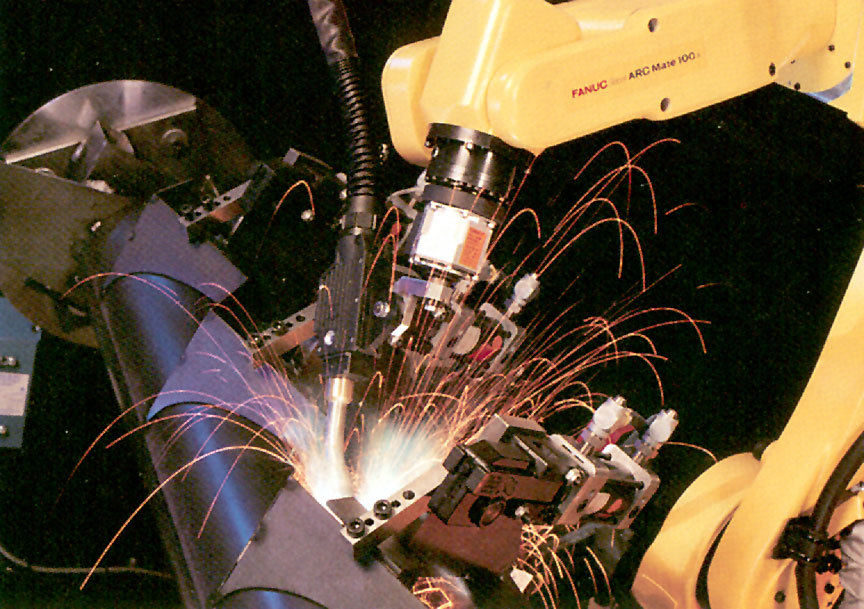

Pulse robotic welding has put BOBALEE in the forefront of technology and productivity. All robotic operations are certified by an independent third party.

BOBALEE has on staff a certified welding inspector and a certified associate welding inspector. In addition, all production welders are certified to AWS D1:1 - 96 specs.

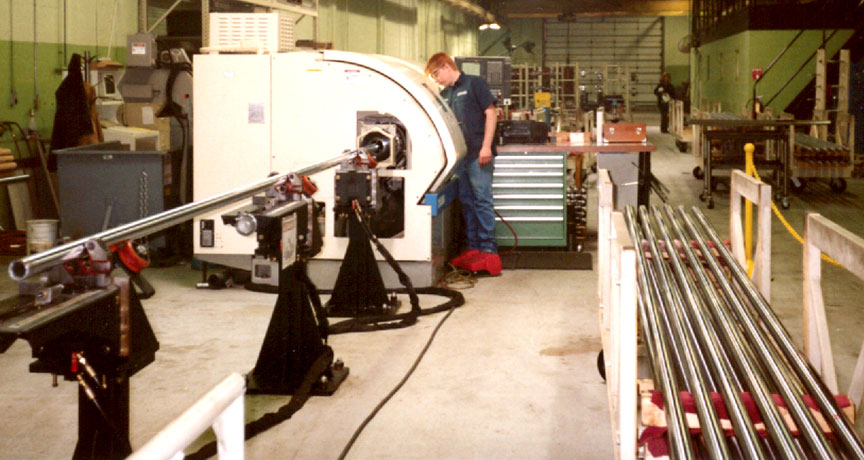

Cell concepts are utilized to ensure maximum efficiency and productivity.

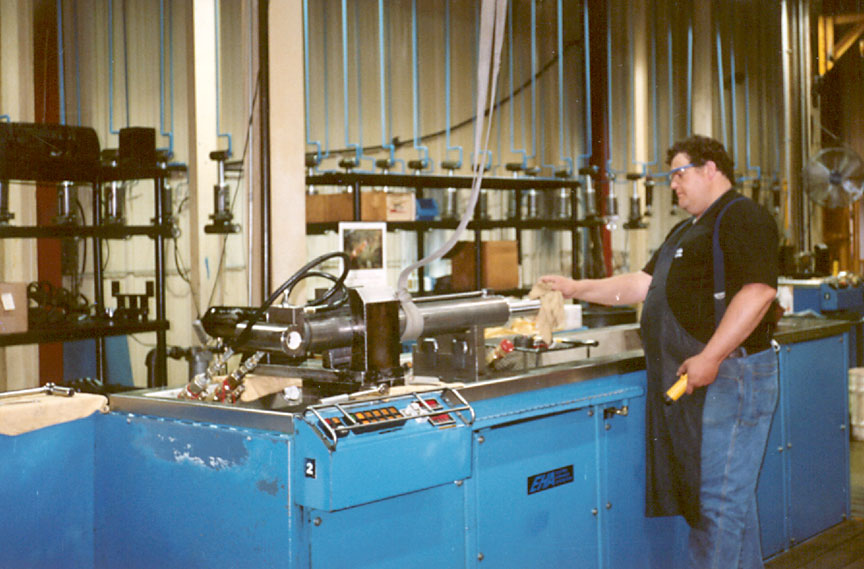

All hydraulic cylinders are 100 percent oil tested on any of four custom-built test stands. The cycle testing pressures exceed engineering specifications.

BOBALEE's dedicated extension cylinder cell combines cell concepts, state-of-the-art equipment and years of experience to provide our customers a competitive edge in the marketplace.

An environmentally controlled self-contained seal room provides a contamination-free environment.

BOBALEE's paint line gives them the flexibility to run several different size cylinders simultaneously, while providing a pre-clean paint and cure system.

Pride, care and packaging protects the final product and your investment.

| Capabilities: |

|

| Integration: |

|

| Conformance: |

|

| Features: |

|